نوفمبر . 09, 2024 16:14 Back to list

Wholesale Centrifuge Oil Filter Solutions for Efficient Filtration Systems

Understanding Wholesale Centrifuge Oil Filters A Comprehensive Guide

In today's fast-paced industrial environment, maintaining the quality of lubricating oils and fluids is paramount for optimal machinery performance. One of the most effective solutions for achieving this is through the use of centrifuge oil filters. This article delves into the world of wholesale centrifuge oil filters, outlining their benefits, applications, and significant considerations when purchasing in bulk.

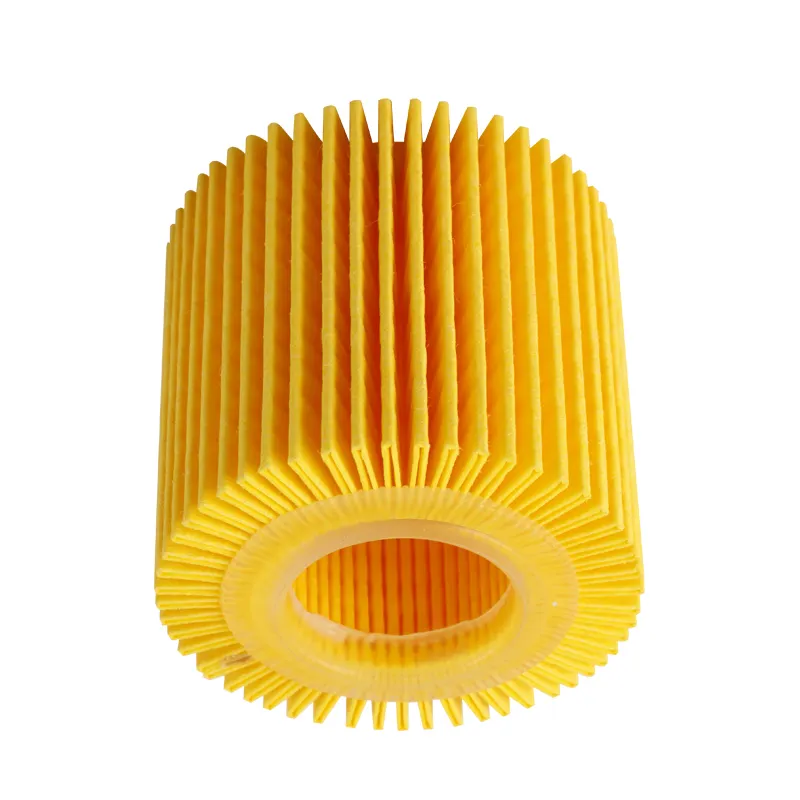

What is a Centrifuge Oil Filter?

A centrifuge oil filter is a sophisticated piece of equipment designed to separate contaminants from lubricating oils through centrifugal force. Unlike traditional filters that rely on physical barriers, centrifuge filters utilize high rotational speeds to generate significant gravitational forces, enabling them to separate solids, water, and other impurities efficiently. This technology results in cleaner oil, prolonging the life of machinery and reducing maintenance costs.

Benefits of Using Centrifuge Oil Filters

1. Enhanced Filtration Efficiency Centrifuge oil filters can remove particles as small as 1-5 microns, making them far superior to conventional filters. This level of filtration ensures that machinery operates smoothly without unnecessary wear and tear.

2. Longevity of Oil Life Regularly filtering oil can significantly extend its usable life by removing harmful contaminants. This not only leads to savings in oil replacement but also contributes to a more sustainable approach to resource management.

3. Reduction in Downtime Keeping machinery well-maintained with clean oil decreases the likelihood of breakdowns. This is crucial in industries where downtime can lead to substantial financial losses.

4. Environmentally Friendly With improved oil life and the reduction of waste oils, centrifuge oil filters present a more eco-friendly solution compared to many traditional methods of oil filtration.

Applications of Centrifuge Oil Filters

Centrifuge oil filters find their applications across various industries, including

wholesale centrifuge oil filter

- Manufacturing In factories where machinery operates continuously, these filters help maintain the cleanliness of hydraulic oils and lubricants. - Marine Ships utilize centrifuge oil filters to keep their engines and lubricating systems clean, essential for long-distance ocean travel. - Automotive In automotive manufacturing, these filters ensure that the lubricants used in assembly lines remain uncontaminated. - Power Generation Power plants use centrifuge filters to maintain the integrity of turbine oils and other critical lubrication systems.

Key Considerations When Purchasing Wholesale Centrifuge Oil Filters

When considering wholesale purchasing, several factors come into play

1. Quality Assurance It's crucial to source centrifuge oil filters from reputable manufacturers. Look for certifications and third-party validations that prove the filters meet quality standards.

2. Compatibility Different machinery requires specific types of filters. Ensure that the filters you are purchasing are compatible with the oils used in your equipment.

3. Cost vs. Value While wholesale purchases can offer cost savings, it’s important to weigh these savings against the filter’s quality and efficiency. Sometimes cheaper filters may lead to higher long-term costs due to ineffective filtration.

4. Supplier Reliability Establishing a relationship with a trustworthy supplier is essential. Assess their track record for delivery, customer service, and technical support.

5. Maintenance and Support Consider the level of support provided, including maintenance services and availability of replacement parts. A supplier who offers comprehensive support can save time and resources in the long run.

Conclusion

Wholesale centrifuge oil filters are essential tools for industries that rely on heavy machinery and equipment. By understanding their functionality, benefits, and applications, businesses can make informed decisions that enhance operational efficiency, reduce costs, and promote sustainability. Investing in quality centrifuge oil filters not only protects machinery but also has a lasting positive impact on an organization’s bottom line. As the industrial landscape evolves, ensuring the purity of lubricants through high-quality filtration systems will remain a priority for many sectors.

-

Toyota Corolla Oil Filter Price & Deals Affordable AC & Air Filters

NewsJun.10,2025

-

Car Air Filter Change How Often & Why Engine & Cabin Filter Guide

NewsJun.10,2025

-

Best 1 Inch Air Filters for Home & Office High Efficiency 1/2 & 2 Inch AC Filter Options

NewsJun.10,2025

-

Whole Home & House Air Filtration Supplier Expert Air Purification Solutions

NewsJun.10,2025

-

Affordable Diesel Engine Filter Price - Best Deals on Quality Parts

NewsJun.10,2025

-

Premium 20x25x5 Air Filter High-Efficiency Dust Removal

NewsJun.09,2025