Ago . 12, 2025 00:20 Back to list

Antiskid Tires: Enhanced Grip & Safety for Your Vehicle

The Critical Role of Automotive Safety and Performance

In the automotive industry, safety and performance are paramount, directly influencing vehicle reliability, driver confidence, and operational efficiency. Central to this is the tire, particularly the antiskid tire, designed to maximize grip and stability under challenging conditions. While tires ensure road contact, the vehicle's internal systems, such as engine lubrication and air filtration, are equally critical for sustained high performance and longevity. A holistic approach to automotive component selection, encompassing everything from advanced tires to high-efficiency filters, ensures optimal operation and adherence to stringent safety standards. This comprehensive strategy is essential for B2B decision-makers focusing on fleet management, automotive manufacturing, or aftermarket solutions, emphasizing the synergy between visible performance elements and crucial hidden components.

Understanding Antiskid Tire Technology and Market Trends

The market for advanced automotive components, including the antiskid tire, is driven by continuous innovation in material science and design. Modern antiskid tires feature specialized tread patterns and rubber compounds that enhance friction and water dispersion, significantly reducing hydroplaning risks and improving braking distances. Key industry trends indicate a growing demand for eco-friendly tires with lower rolling resistance for fuel efficiency, coupled with an emphasis on durability and reduced noise levels. These innovations are often supported by computational fluid dynamics (CFD) and finite element analysis (FEA) during the design phase, optimizing performance before physical prototyping. The integration of smart tire technologies, such as pressure monitoring and wear sensors, further underscores the industry's commitment to proactive safety and maintenance.

The global automotive aftermarket is also seeing a surge in demand for quality replacement parts, from `toyota corolla cabin air filter canadian tire` and `toyota corolla air filter canadian tire` to high-performance tires. Consumers and businesses alike are increasingly seeking components that offer OE (Original Equipment) quality or better, focusing on long-term value and reliability. This trend necessitates manufacturers to not only innovate in core product design but also to ensure robust supply chains and consistent quality control across their diverse product lines, catering to specific vehicle models like Hyundai Elantra requiring a new `hyundai elantra air filter`, or specialized parts like a `china bryant air filter` or `oem bryant air filter` for HVAC systems within vehicles, highlighting the broad spectrum of filtration needs.

Precision Engineering: The Manufacturing Process of Advanced Antiskid Tires

The production of a high-performance antiskid tire is a complex, multi-stage engineering feat, combining material science with advanced manufacturing techniques. The process begins with meticulous material preparation, involving the precise compounding of natural and synthetic rubbers with additives like carbon black, silica, and polymers to achieve specific performance characteristics such as grip, wear resistance, and fuel efficiency. This blend forms the foundation for the tire's body, tread, and sidewalls.

- Component Preparation: Rubber compounds are processed into various components—calendered into sheets for plies and belts, extruded for treads and sidewalls, and reinforced with steel or fabric cords.

- Tire Building: These components are then assembled layer by layer onto a building drum, forming a "green tire." This stage requires exceptional precision to ensure uniformity and structural integrity, critical for the final antiskid tire's balance and performance.

- Curing (Vulcanization): The green tire is placed in a curing press where heat and pressure are applied. This process molds the tire into its final shape, imprinting the designed tread pattern, including the intricate sipes and grooves essential for antiskid properties. It also chemically cross-links the rubber molecules, enhancing durability, elasticity, and heat resistance.

While direct `casting`, `forging`, or `CNC processing` are not typical for rubber components of a tire, these sophisticated manufacturing principles underpin the creation of tire molds and the high-precision machinery used throughout the production line. For instance, CNC machining ensures the absolute precision of molds that define the antiskid tire's complex tread patterns. Rigorous detection standards, including ISO 9001, IATF 16949, and often specific ANSI/ASTM standards for tire testing, are applied at every stage to guarantee quality. This ensures products like the antiskid tire, or indeed an OEM Car Oil Filter, meet strict performance benchmarks, offering an optimal service life and superior performance in applicable industries such as general automotive, heavy equipment, and commercial transport.

Beyond Traction: The Synergy of Vehicle Components

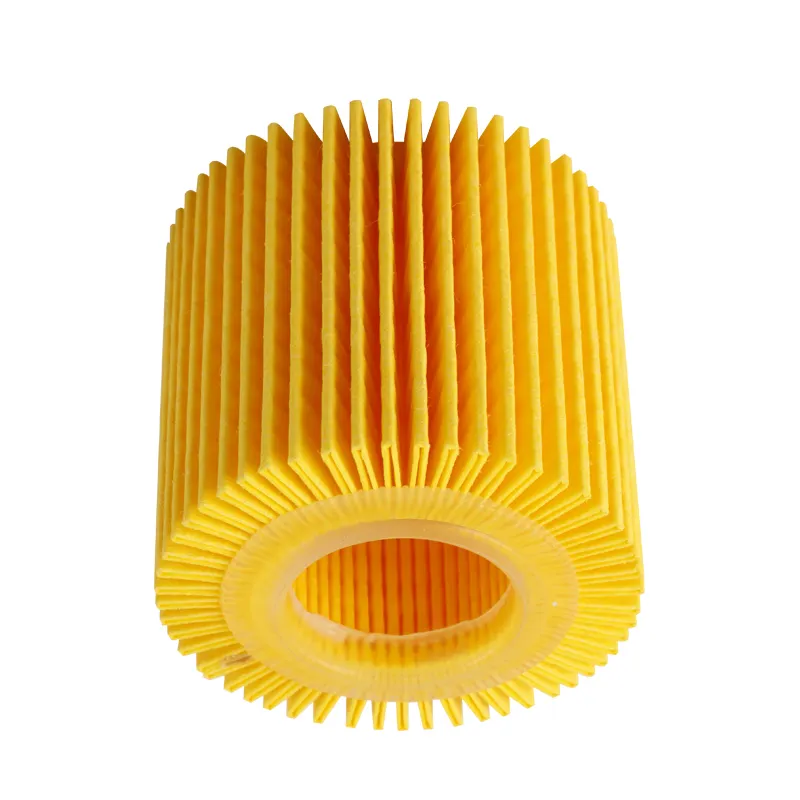

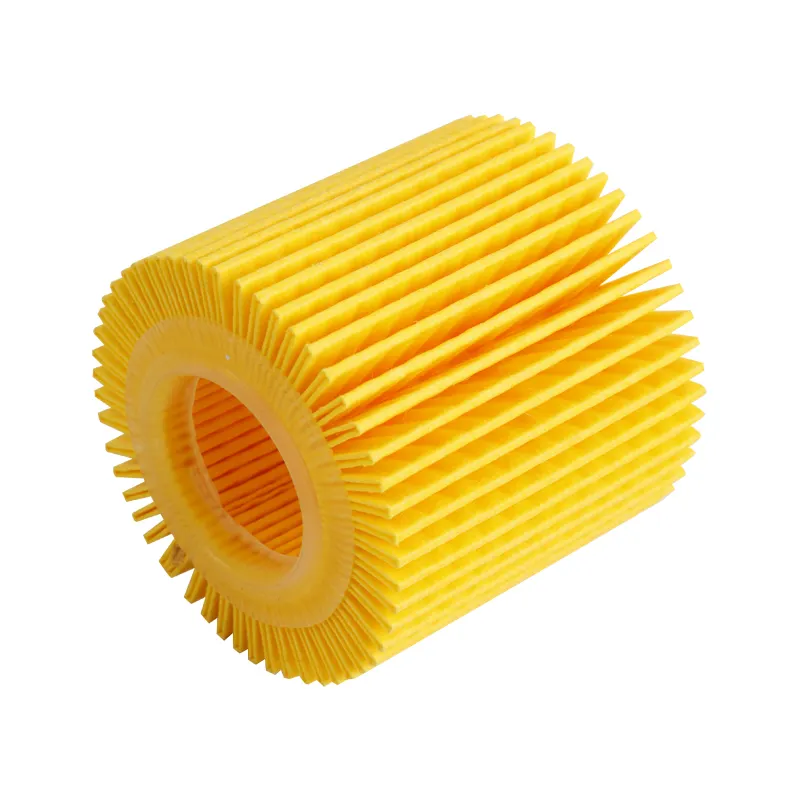

While a robust antiskid tire ensures direct road contact and safety, the broader health of a vehicle relies on the harmonious operation of numerous critical components. Engine health, for instance, is inextricably linked to the quality of its lubrication system and air intake. This is where components like the OEM Car Oil Filter 04152-37010 04152-YZZA6 play an indispensable role. This specific oil filter, designed for optimal filtration efficiency, removes contaminants from engine oil, preventing wear and tear on vital engine parts and extending the engine's lifespan. Its precise fit and filtration capabilities contribute directly to fuel economy and emissions control, making it a cornerstone of engine maintenance for various Toyota models.

Similarly, air filtration is paramount for both engine performance and cabin air quality. An efficient `toyota corolla air filter canadian tire` ensures clean air reaches the engine, preventing dust and debris from compromising combustion and engine components. For passengers, a `toyota corolla cabin air filter canadian tire` is essential for trapping pollen, dust, and pollutants, contributing to a healthier in-cabin environment. Specialized filters, such as a `hyundai elantra air filter`, or industrial-grade solutions like a `china bryant air filter` or `oem bryant air filter` used in vehicle HVAC systems, highlight the diverse and critical need for high-quality filtration across the automotive ecosystem. Just as an antiskid tire performs optimally with superior materials and design, these filtration components require advanced media and construction to deliver peak performance and protection.

Technical Specifications & Performance Benchmarks

Understanding the technical specifications of critical automotive components is vital for informed decision-making. Below is a comparative overview of typical parameters for high-performance antiskid tires, emphasizing features that contribute to their superior safety and operational characteristics. This data is derived from industry benchmarks and testing protocols, providing a clear picture of expected performance levels under various driving conditions.

| Parameter | Description | Typical Value Range (High-Performance Antiskid Tire) |

|---|---|---|

| Tread Depth (New) | Initial groove depth for water evacuation and grip. | 8-12 mm |

| Wet Braking Distance (80km/h to 0) | Distance required to stop on a wet surface. | < 35 meters (on standard test surfaces) |

| Hydroplaning Resistance Speed | Speed at which tire begins to lose contact with road due to water. | > 85 km/h (on 7mm water film) |

| Rolling Resistance Coefficient (RRC) | Measure of energy loss due to tire deformation; impacts fuel economy. | 0.0075 - 0.0095 (Class A/B EU Label) |

| Noise Level | External noise generated by tire rotation. | < 70 dB (Class A EU Label) |

| Expected Service Life (Mileage) | Estimated distance before tread reaches wear indicators. | 50,000 - 80,000 km (variable by driving style/conditions) |

These benchmarks illustrate the performance capabilities that define a premium antiskid tire. Similarly, an OEM Car Oil Filter like the 04152-37010 04152-YZZA6 undergoes stringent flow rate, pressure drop, and filtration efficiency tests to ensure it meets or exceeds original equipment specifications, guaranteeing engine protection. For example, its filtration efficiency often exceeds 99% for particles above 20 microns, and it is designed to withstand typical engine operating pressures without compromising flow.

Applications and Strategic Advantages

The applications of a high-quality antiskid tire span a broad spectrum of automotive sectors, from passenger vehicles and commercial fleets to specialized industrial applications. In passenger cars, these tires are crucial for everyday safety, particularly in regions with varying weather conditions, contributing to accident prevention and passenger comfort. For commercial fleets, they translate directly into operational reliability, reduced downtime, and enhanced safety for cargo and personnel. The advanced designs provide superior grip on wet, icy, or loose surfaces, significantly enhancing vehicle control and stability. This inherent safety advantage reduces accident risks, potentially lowering insurance premiums and maintenance costs over the vehicle's lifespan.

Beyond tires, the strategic advantages of using OEM-grade components extend to engine and cabin filtration. For instance, the OEM Car Oil Filter 04152-37010 04152-YZZA6 provides superior engine protection, translating to extended engine life and reduced need for costly overhauls. This directly impacts total cost of ownership (TCO) for fleet operators and individual vehicle owners. Similarly, a premium `toyota corolla cabin air filter canadian tire` improves occupant health and comfort by effectively filtering out pollutants and allergens, which can be critical for professional drivers spending long hours on the road. The use of specialized `hyundai elantra air filter` or a high-quality `oem bryant air filter` in specific vehicle models underscores the need for precision-engineered components that offer both energy efficiency and anti-corrosion properties in their relevant applications, contributing to the overall vehicle's longevity and performance in diverse environments, from general road use to demanding industrial settings like petrochemical plants or water treatment facilities where specialized vehicle fleets operate.

Choosing a Reliable Partner: Manufacturer Comparison and Custom Solutions

Selecting the right manufacturer for automotive components is crucial for ensuring product quality, reliability, and long-term support. When evaluating suppliers for products like the antiskid tire or specialized filters, key considerations include adherence to international standards (e.g., ISO 9001, IATF 16949 for automotive), product testing methodologies, and after-sales service. Leading manufacturers distinguish themselves through robust R&D capabilities, utilizing advanced simulation tools and state-of-the-art testing facilities to validate product performance under extreme conditions. For instance, reputable providers of antiskid tires will showcase extensive test data on wet braking, handling, and wear characteristics, often surpassing regulatory minimums.

Beyond standard offerings, many B2B clients require customized solutions tailored to specific vehicle models or operational environments. This might involve developing a proprietary rubber compound for a unique antiskid tire application in challenging terrains or designing a custom filtration system for specialized industrial vehicles. A flexible and capable manufacturing partner can provide design modifications, material alterations, and optimized production runs, ensuring the bespoke solution meets precise performance requirements and budget constraints. This collaborative approach fosters innovation and ensures that components, whether a `china bryant air filter` or an OEM Car Oil Filter, integrate seamlessly into existing systems, delivering peak efficiency and reliability for diverse applications.

Real-World Impact: Customer Success Stories and Service Excellence

The true measure of a component's efficacy lies in its real-world performance and the positive feedback from end-users. A major logistics company, for example, reported a significant reduction in accident rates and enhanced driver confidence after upgrading their fleet with premium antiskid tires, particularly during winter operations. This not only improved safety but also led to quantifiable savings in vehicle damage and insurance claims. Similarly, a regional public transport authority noted a substantial increase in engine longevity and reduced maintenance intervals for their bus fleet by consistently using high-quality OEM Car Oil Filter 04152-37010 04152-YZZA6, illustrating the long-term economic benefits of superior filtration.

Customer testimonials frequently highlight the measurable impact of reliable automotive components. One automotive repair shop owner recounted how switching to a quality `hyundai elantra air filter` from an unreliable generic brand led to fewer customer complaints about engine performance and improved fuel efficiency, enhancing their reputation. These success stories underscore the critical importance of selecting components that are not only technically sound but also backed by robust customer support and a clear understanding of practical application challenges. Our commitment extends beyond product delivery to comprehensive after-sales service, technical assistance, and proactive maintenance advice, ensuring our partners achieve maximum operational uptime and sustained performance across their vehicle fleets.

Ensuring Trust: FAQs, Warranty, and Support

Frequently Asked Questions (FAQs)

- Q: What makes an antiskid tire superior to a standard tire?

A: Antiskid tires feature advanced tread designs, specialized rubber compounds, and siping technologies to maximize grip and water dispersion, significantly enhancing traction and reducing braking distances on wet or slippery surfaces compared to standard tires. - Q: How often should I replace my OEM Car Oil Filter 04152-37010 04152-YZZA6?

A: For optimal engine health, it is recommended to replace the oil filter at every oil change, typically every 5,000 to 10,000 miles or as per your vehicle manufacturer's recommendations. - Q: What is the benefit of an OEM `toyota corolla cabin air filter canadian tire`?

A: An OEM cabin air filter ensures proper fit and filtration efficiency, effectively blocking dust, pollen, and pollutants from entering the vehicle's cabin, thereby improving air quality and passenger comfort. - Q: Are your products certified to international standards?

A: Yes, our manufacturing processes and products, including our OEM Car Oil Filter and similar automotive components, adhere to stringent international quality standards such as ISO 9001 and IATF 16949, ensuring consistent quality and performance.

Delivery Cycle and Quality Assurance

Our commitment to efficiency and reliability extends to our delivery schedules. Standard orders typically have a lead time of 7-14 business days, with expedited options available for urgent requirements. Custom orders may vary based on complexity and volume. Each product undergoes rigorous multi-point inspection before dispatch, ensuring it meets our exacting quality standards. Our OEM Car Oil Filter 04152-37010 04152-YZZA6, for example, is subjected to burst strength, pressure drop, and filtration efficiency tests to guarantee superior performance. This meticulous approach minimizes defects and ensures that products such as a antiskid tire or a `toyota corolla air filter canadian tire` arrive ready for immediate installation and optimal function.

Warranty and Customer Support

We stand behind the quality and performance of our products with a comprehensive warranty program. All OEM Car Oil Filter units come with a 12-month or 20,000-mile (whichever comes first) limited warranty against manufacturing defects. Similar warranty terms apply to our full range of automotive components, including antiskid tires where applicable, and various air filtration solutions like the `hyundai elantra air filter`. Our dedicated customer support team is available to assist with technical queries, order tracking, and warranty claims, ensuring a seamless experience from inquiry to after-sales service. We pride ourselves on building lasting partnerships based on trust, quality, and unparalleled support, reinforcing our position as a reliable supplier in the B2B automotive sector.

Concluding Thoughts & Future Outlook

The continuous evolution of automotive technology demands components that not only meet current performance standards but also anticipate future needs. The antiskid tire, alongside high-efficiency filtration systems like the OEM Car Oil Filter and various cabin and engine air filters, represents the forefront of this innovation. As vehicles become more sophisticated and environmental regulations tighten, the synergy between these vital parts will become even more critical for overall vehicle integrity and user safety. Investing in superior quality components from reputable manufacturers ensures that fleets and individual vehicles alike can operate at their peak, minimizing operational costs and maximizing long-term reliability.

Our commitment to research and development ensures we remain at the cutting edge of automotive component technology, providing solutions that empower our clients to achieve their operational and safety objectives. We strive to be the preferred partner for businesses seeking dependable, high-performance parts, contributing to a safer, more efficient, and sustainable automotive future.

References

- National Highway Traffic Safety Administration (NHTSA) – Tire Safety and Performance Standards.

- Society of Automotive Engineers (SAE International) – Automotive Component Design and Testing Protocols.

- International Organization for Standardization (ISO) – Quality Management Systems (ISO 9001, IATF 16949).

- European Tyre and Rim Technical Organisation (ETRTO) – Tire Technical Data and Standards.

- Filter Manufacturers Council (FMC) – Filtration Industry Standards and Best Practices.

-

OEM Car Air Filters - QINGHE COUNTY ANNAITE AUTO PARTS CO.,LTD | Efficient Filtration, OEM/ODM Services

NewsAug.12,2025

-

Antiskid Tires: Enhanced Grip & Safety for Your Vehicle

NewsAug.12,2025

-

High-Quality Car Air Filter Manufacturer-OEM Quality 17801-31090/17801-0P010|High Filtration Efficiency,Durable Construction

NewsAug.11,2025

-

Car Air Filter 17801-31090, 17801-0P010 OEM Quality | QINGHE COUNTY ANNAITE AUTO PARTS CO.,LTD

NewsAug.11,2025

-

China Fuel Filter Supplier: Quality Fuel Oil & Auto Filters

NewsAug.11,2025

-

High-Quality Car Air Filter Manufacturer - 17801-31090 / 17801-0P010 OEM Quality | QINGHE COUNTY ANNAITE AUTO PARTS CO.,LTD

NewsAug.11,2025