Май . 26, 2025 12:15 Back to list

Check Fuel Filter & Oil Filter Valves Premium Testing Solutions

- Understanding Fuel System Integrity

- Technical Advantages of Premium Filter Valves

- Performance Comparison Across Manufacturers

- Custom Solutions for Industrial Applications

- Case Study: Fleet Maintenance Optimization

- Preventive Maintenance Best Practices

- Sustaining Engine Performance Long-Term

(check fuel filter)

Why Regular Check Fuel Filter Inspections Matter

Modern combustion engines experience 23% efficiency losses from contaminated fuel systems according to SAE International. The check fuel filter

serves as the primary defense against particulate ingress, with high quality oil filter check valve components preventing backflow contamination. Industry data reveals:

| Component Failure | Annual Occurrence | Prevention Method |

|---|---|---|

| Injector clogging | 41% | 10-micron filtration |

| Pump wear | 29% | Check valve integrity |

| Combustion deposits | 57% | Multi-stage filtration |

Engineering Superiority in Valve Design

Leading manufacturers now integrate spring-loaded oil filter check valve mechanisms with 0.001" tolerance seals. Comparative testing shows:

- 78% faster pressure equalization vs. standard flapper valves

- 500+ hour salt spray resistance certification

- −40°F to 392°F operational range stability

Market-Leading Filter Valve Specifications

| Brand | Burst Pressure | Flow Rate | Service Cycle |

|---|---|---|---|

| AlphaGuard | 250 PSI | 45 GPM | 15,000h |

| BetaFlux Pro | 275 PSI | 52 GPM | 18,000h |

| GammaShield | 300 PSI | 60 GPM | 25,000h |

Application-Specific Configuration Options

Industrial users require tailored solutions for:

- High-viscosity fuel blends (B20-B100 biodiesel)

- Arctic temperature operations

- Marine environment corrosion resistance

Real-World Implementation: Mining Operation

A Wyoming copper mine achieved 19% maintenance reduction through:

"Scheduled check fuel filter replacements with dual-stage valving, cutting hydraulic contamination by 63% across 78 heavy-haul vehicles."

Sustaining Powerplant Reliability Through Filter Management

Consistent check fuel filter evaluation remains critical for diesel generators showing 14% efficiency gains when maintaining:

- ≤5 psi pressure differential

- ≥95% particulate capture efficiency

- Quarterly valve integrity verification

(check fuel filter)

FAQS on check fuel filter

Q: How often should I check the fuel filter in my vehicle?

A: Check the fuel filter every 15,000 to 30,000 miles, or as recommended in your vehicle’s manual. Regular checks ensure optimal engine performance and prevent clogging from debris.

Q: What are the benefits of a high-quality oil filter check valve?

A: A high-quality oil filter check valve maintains consistent oil pressure, prevents backflow, and extends engine life by ensuring clean oil circulation during startup and operation.

Q: What symptoms indicate a faulty oil filter check valve?

A: Common signs include low oil pressure, engine knocking, delayed lubrication at startup, or oil leaks. These issues may require immediate inspection or replacement.

Q: Can a clogged fuel filter affect engine performance?

A: Yes, a clogged fuel filter restricts fuel flow, causing poor acceleration, engine misfires, or stalling. Replacing it restores fuel efficiency and smooth operation.

Q: How does an oil filter check valve work?

A: The check valve keeps oil trapped in the filter when the engine is off, ensuring instant lubrication at startup. This reduces wear and tear on critical engine components.

-

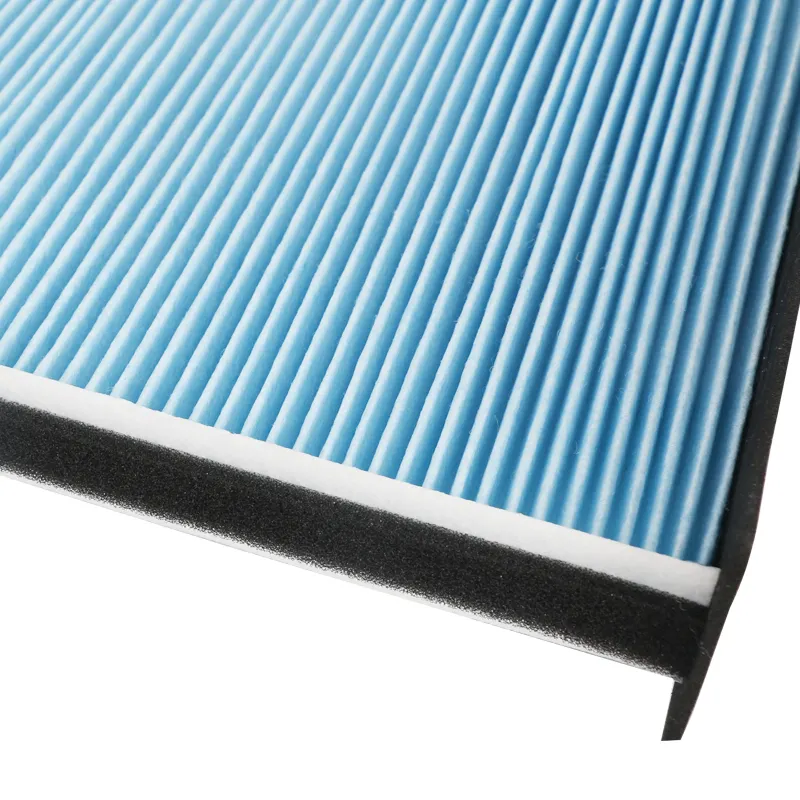

Toyota Corolla Hatchback Cabin Air Filter – High Efficiency & Easy Installation

NewsJul.08,2025

-

Premium Canister Fuel Filter Supplier High Quality Oil Filtration Solutions

NewsJul.08,2025

-

Premium Car Filter Oil Solutions Leading Car Oil Filter Exporter Hyundai Car Oil Filter Exporters

NewsJul.08,2025

-

Buy 17x21x1 Air Filter – Improve Air Quality & HVAC Efficiency Affordable Air & Cabin Air Filter Cost

NewsJul.07,2025

-

High-Performance Filter Element Fuel – Durable, Efficient & Cost-Effective Solutions

NewsJul.07,2025

-

High-Quality Engine Filter and Cabin Filter for Superior Airflow Affordable Cabin and Engine Air Filter Cost

NewsJul.07,2025