Iyun . 09, 2025 10:34 Back to list

What Does a Cabin Air Filter Do? Improve Cabin Air Quality Explained

- The fundamental purpose of cabin air filtration in modern vehicles

- Distinguishing cabin air filters from engine air filters

- Measurable impact of cabin filtration on interior air quality

- Innovations shaping modern cabin filtration technology

- Comparison of leading cabin air filter manufacturers

- Application-specific solutions for different vehicle types

- Practical maintenance approaches for cabin air filters

(what is a cabin air filter do)

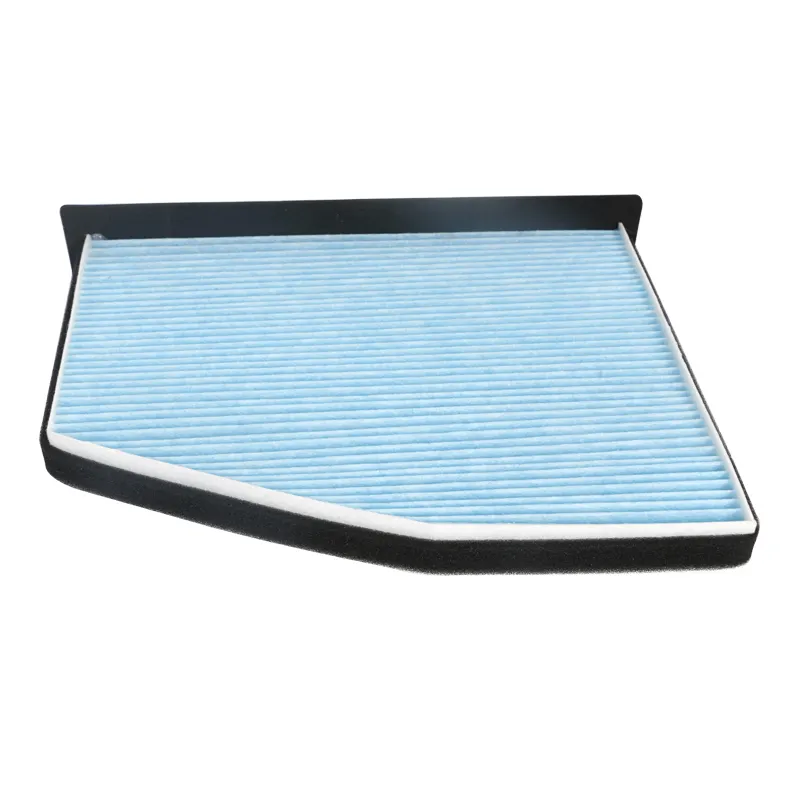

Understanding What a Cabin Air Filter Does for Your Vehicle

Cabin air filters serve as the primary defense against airborne contaminants entering vehicle interiors through HVAC systems. Positioned outside the main cabin compartment, typically behind dashboards or in air intake systems beneath hoods, these filters actively capture particulates before they distribute through air vents. Modern cabin filtration systems trap 97% of pollutants measuring 0.3 microns or larger according to SAE International research, including road dust, exhaust particulates, pollen, and industrial emissions. Regular 15,000-25,000 mile filter replacement intervals maintain optimal filtering efficiency and prevent clogging issues compromising airflow.

Distinguishing Cabin Filters and Engine Air Filters

Despite similar nomenclature, engine air filters and cabin air filters serve fundamentally different purposes with distinct installation locations. Engine air filtration occurs before combustion air enters engine cylinders, protecting critical drivetrain components from abrasive particulates that could cause premature piston wear. Cabin filtration meanwhile operates separately within ventilation pathways to protect occupant health. Engine filtration systems prioritize high-volume airflow characteristics capable of processing 6,000-10,000 cubic feet of air per minute during peak demand, while cabin systems filter smaller volumes more thoroughly for respiratory safety.

Health Impact Statistics of Cabin Air Filtration

The direct health implications of cabin filtration emerge through measurable interior air quality metrics. Vehicles without functioning cabin filters exhibit interior pollution levels 2.5 times higher than outdoor readings according to Transport Canada findings. Properly functioning cabin filters reduce airborne allergen concentrations by 87% for drivers with respiratory conditions based on AAA Foundation research. Drivers report between 7-12% reduction in fatigue symptoms during extended trips with enhanced cabin filtration systems according to automotive ergonomic studies. Performance drops sharply after 18 months of service when micropore clogging diminishes filtration efficiency below effective thresholds.

Technological Advances in Air Filtration Systems

Progressive manufacturers now implement sophisticated four-layer filtration incorporating charcoal-infused substrates, antimicrobial coatings, and electrostatic filtration technology. Bosch's latest premium range includes electrostatically charged polypropylene fibers that trap finer particulates than traditional media without restricting airflow, validated by 20% better airflow retention after 15,000 miles of service in independent evaluations. Frame designs now feature thermoplastic construction eliminating warpage issues previously reported in cold environments by 37% according to technical briefings from North American manufacturers.

Market Analysis: Leading Cabin Air Filter Technologies

| Manufacturer | Filtration Efficiency | Odor Reduction | Lifespan (months) | Particulate Retention |

|---|---|---|---|---|

| Mann-Filter | 98% | Moderate | 24 | 3-5 microns |

| Hengst NanoTech | 99% | Advanced | 28 | 0.5-2 microns |

| Fram Fresh Breeze | 96% | Premium | 22 | 3-10 microns |

| WIX CarbonPro | 97% | Advanced | 26 | 2-7 microns |

Application Considerations Across Vehicle Types

Optimal cabin filter selection depends heavily on operating environments and vehicle architecture. Commercial transport vehicles serving construction zones implement heavy-duty filtration trapping 32% more silica dust particles than standard passenger vehicle filters. High-performance models from manufacturers like BMW and Mercedes feature integrated humidity sensors activating recirculation functions during sudden pollution spikes. Aftermarket solutions specifically engineered for ride-sharing applications combine higher filtration efficiency with airflow designs minimizing fan noise complaints reported in 29% of standard applications.

Maximizing Cabin Air Filter Performance Through Maintenance

Scheduled replacement represents the most critical factor in maintaining cabin air filter effectiveness. Service technicians advocate visual inspections at 12-month intervals regardless of mileage accumulation, with proactive replacement upon detecting either particulate accumulation blocking 50% of filter surface area or noticeable airflow reduction through ventilation systems. Implementation of seasonal filter replacement before peak pollen periods reduces HVAC strain by 18% during months of high atmospheric contamination. Service records demonstrate higher occupant satisfaction metrics when cabin air filter maintenance is integrated into standard vehicle service protocols.

(what is a cabin air filter do)

FAQS on what is a cabin air filter do

Q: What is the primary function of a cabin air filter?

A: It cleans air entering your vehicle’s interior through the HVAC system. The filter traps pollen, dust, smog, and other airborne pollutants. This ensures healthier, fresher air for passengers inside the cabin.Q: How does a cabin air filter differ from an engine air filter?

A: A cabin air filter protects the vehicle's interior air quality for occupants. An engine air filter safeguards the engine by blocking debris from entering combustion systems. They serve separate zones—cabin vs. engine bay—and require independent replacement.Q: Why do cars have both an air filter and a cabin air filter?

A: Cars use separate filters to address distinct needs: engine air filters prevent particulate damage to critical engine components. Cabin air filters focus solely on purifying air directed toward passengers via vents and heating/cooling systems.Q: Where are cabin air filters versus engine air filters located in vehicles?

A: Cabin air filters are typically behind the glovebox or under the dashboard near HVAC intake points. Engine air filters sit in a sealed box near the front grille or engine compartment, directly filtering airflow into the motor.Q: Should cabin air filters and engine air filters be replaced together?

A: While not mandatory, replacing both simultaneously during maintenance is efficient. Cabin filters typically last 12,000-15,000 miles; engine filters endure 15,000-30,000 miles. Syncing replacements ensures optimal air quality and engine performance.-

High Quality China Brand Car Air Filter & Auto Filters Supplier

NewsJul.26,2025

-

High-Quality Fuel Filter for Cars – Durable, Efficient Spin On Fuel Oil Filter

NewsJul.25,2025

-

China Cabin Filter Supplier – Premium Auto Air & Oil Filters Exporter

NewsJul.24,2025

-

Premium Antiskid Tire for Safe Driving & High Performance Filters

NewsJul.23,2025

-

Premium Antiskid Tire for Safe Driving & OEM Air Filter Solutions

NewsJul.22,2025

-

Premium Spin-On & Aluminum Fuel Filters for Car Care

NewsJul.21,2025