Aug . 21, 2025 18:40 Back to list

Reliable China Cabin Filter Supplier | Quality Car Filters

Navigating the Global Automotive Filtration Market: Insights from a Leading China Cabin Filter Supplier

The air we breathe inside our vehicles significantly impacts comfort, health, and driving experience. As global awareness concerning air quality escalates, the demand for highly efficient automotive filtration solutions, particularly cabin air filters, has seen exponential growth. At the forefront of this critical industry are leading manufacturers, including a prominent china cabin filter supplier. These suppliers play a pivotal role in delivering cutting-edge filtration technology to the automotive aftermarket and original equipment manufacturers (OEMs) worldwide. Their ability to combine advanced manufacturing capabilities with cost-effective solutions has positioned them as indispensable partners in maintaining vehicle interior air purity.

The market for automotive filters is dynamic, driven by stringent environmental regulations, increasing vehicle parc, and a growing consumer emphasis on in-cabin air quality. From preventing allergens and dust from entering the cabin to neutralizing harmful gases and odors, a high-quality filter is an essential component for modern vehicles. Understanding the intricacies of this market, from manufacturing processes to technical specifications, is crucial for B2B decision-makers seeking reliable and innovative filtration partners.

Industry Trends and Market Dynamics for a China Cabin Filter Supplier

The global automotive filter market, valued at approximately USD 15-20 billion annually, continues to expand, with projections indicating a Compound Annual Growth Rate (CAGR) of 4-6% over the next five years. Key growth drivers include the rising global vehicle production, increasing average vehicle age, and stricter emission norms. A significant trend observed by any proactive china cabin filter supplier is the shift towards multi-layered and activated carbon filters, which offer superior protection against particulate matter (PM2.5), volatile organic compounds (VOCs), and noxious gases. This evolution is directly linked to escalating concerns over urban air pollution and its impact on human health.

- Emphasis on Health & Wellness: Consumers are increasingly prioritizing interior air quality, leading to higher demand for filters that capture ultrafine particles, allergens, and bacteria.

- Electrification of Vehicles: While electric vehicles (EVs) don't have engine air filters or fuel filters, their increasing adoption still drives demand for advanced cabin air filters, as manufacturers focus on creating premium in-cabin environments.

- Smart Filter Technology: The future holds potential for smart filters equipped with sensors that monitor air quality and indicate when replacement is due, optimizing maintenance schedules.

- Sustainability in Materials: Research into biodegradable and recyclable filter media is gaining traction, reflecting the industry's commitment to environmental responsibility.

These trends necessitate continuous innovation in filter media technology, material science, and manufacturing processes for any competitive china car air filter supplier and china car cabin filter supplier. Suppliers must adapt swiftly to market demands, offering products that not only meet but exceed performance expectations.

Technical Specifications and Parameters: The Core of Filtration Performance

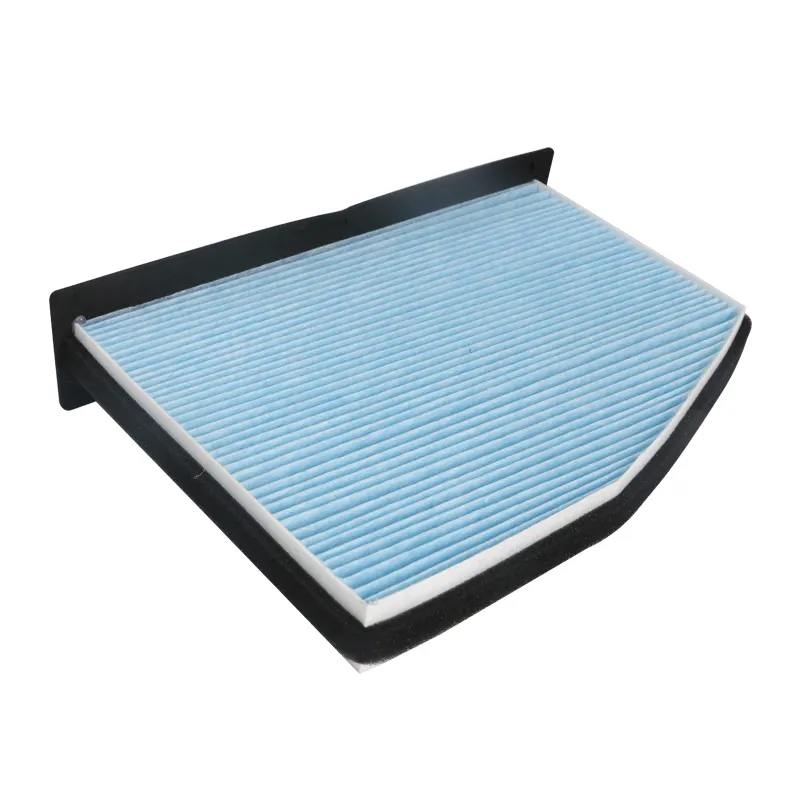

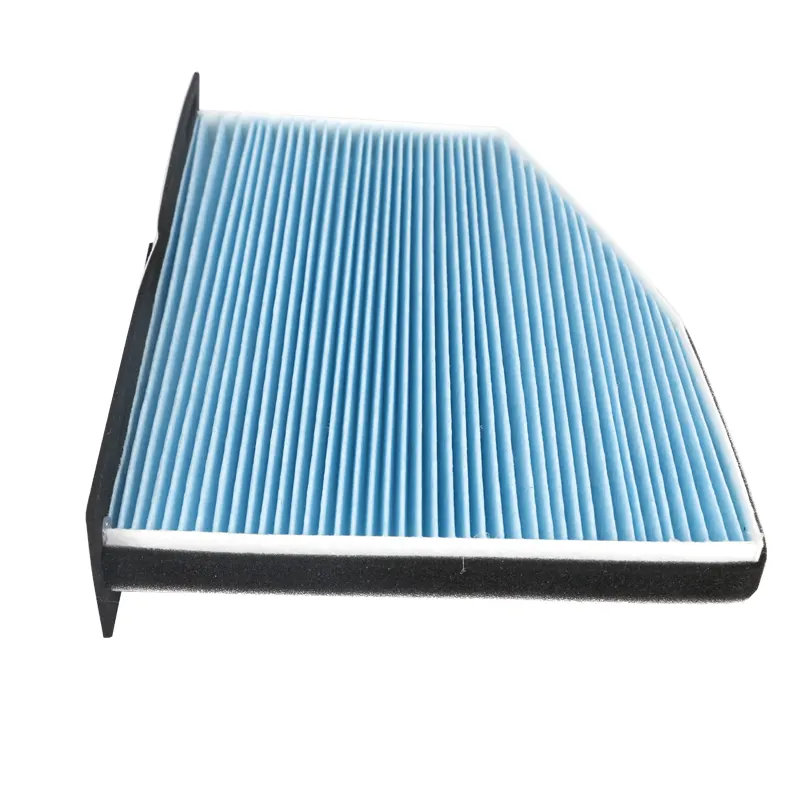

Understanding the technical parameters of cabin air filters is paramount for evaluating their effectiveness. Our featured product, the Car Air Cabin Filter OEM 1987432397 1K1819653, exemplifies the high standards achieved by leading manufacturers. Key parameters include filtration efficiency, pressure drop, dust holding capacity, and material composition.

Manufacturers like our featured china cabin filter supplier often adhere to international testing standards such as ISO 11155-1 for particle filters and ISO/TS 19713-1 for combined filters (particle and gas). These standards ensure consistent quality and performance across different production batches and suppliers.

The Meticulous Manufacturing Process of a China Cabin Filter Supplier

The production of high-quality cabin air filters is a sophisticated process that blends material science with precision engineering. A reputable china cabin filter supplier employs advanced manufacturing techniques to ensure product reliability and consistent performance. While specific processes can vary, the general workflow is as follows:

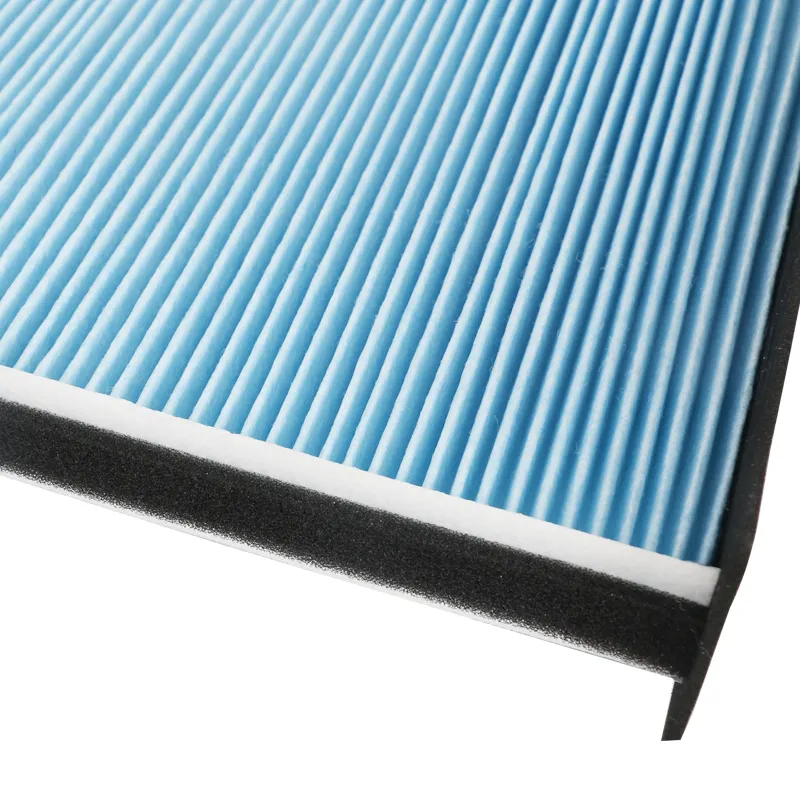

- Media Selection and Preparation: This is the foundational step. High-grade non-woven synthetic fibers (e.g., polyester, polypropylene) are chosen for particle filtration. For combined filters, layers of activated carbon granules are integrated or coated onto the media. The choice of material is critical for achieving desired filtration efficiency (e.g., for PM2.5 or finer particles) and dust holding capacity.

- Pleating: The selected filter media is precisely pleated to maximize the effective filtration surface area within the limited space of a vehicle's HVAC system. Automated pleating machines ensure uniform pleat height and spacing, which is vital for optimal airflow and efficiency. This process prevents media collapse and premature clogging, ensuring a longer lifespan.

- Frame Molding: Durable and often thermoplastic materials (like polypropylene or polyurethane) are molded to create the filter frame. This frame provides structural rigidity, prevents air bypass around the filter media, and facilitates easy installation into the vehicle's filter housing. Precision molding, often involving injection molding techniques, ensures exact fitment according to OEM specifications.

- Media Sealing and Assembly: The pleated media pack is meticulously sealed within the molded frame. This typically involves hot-melt adhesives or ultrasonic welding, creating an airtight seal that forces all incoming air through the filter media, preventing unfiltered air from bypassing the system. Automation is heavily utilized here for consistency and speed.

- Quality Control & Testing: Throughout the production line, rigorous quality control checks are implemented. This includes visual inspections, dimensional checks (ensuring adherence to OEM specifications like those for the Car Air Cabin Filter OEM 1987432397 1K1818653), and performance testing. Filters undergo tests for initial pressure drop, filtration efficiency (e.g., using standardized test dust), and dust holding capacity according to international standards such as ISO 11155 or DIN 71460. Some advanced suppliers also conduct leak tests and acoustic tests.

- Packaging and Distribution: Once verified, filters are carefully packaged to prevent damage during transit and storage, ready for global distribution to aftermarket retailers, distributors, and OEM assembly lines.

The emphasis on automated processes, stringent material selection, and continuous in-line inspection showcases the technical prowess of leading china cabin filter supplier companies. This commitment to precision manufacturing is what distinguishes a reliable supplier in the competitive global market.

Application Scenarios and Technical Advantages of Advanced Cabin Air Filters

Modern cabin air filters are indispensable across a wide spectrum of automotive applications, from passenger cars to heavy-duty commercial vehicles. Their primary role is to protect vehicle occupants from airborne pollutants, but they also safeguard the vehicle's HVAC system.

- Urban Commuting: In highly polluted urban environments, multi-layer filters with activated carbon are crucial for filtering out exhaust fumes, industrial pollutants (like SOx, NOx), ozone, and fine particulate matter (PM2.5, PM10). This is where a high-efficiency china car cabin filter supplier truly adds value.

- Rural/Dusty Environments: Vehicles operating in agricultural areas or construction sites benefit from filters with high dust holding capacity, preventing premature clogging and maintaining optimal airflow.

- Allergy Sufferers: Filters with enhanced pollen and allergen retention capabilities provide significant relief to individuals prone to respiratory issues.

- Luxury and Premium Vehicles: OEMs for high-end vehicles often demand the most advanced filtration systems, including multi-stage filters with anti-microbial layers, to provide a superior in-cabin experience.

- Public Transport & Fleet Vehicles: Given the high occupancy and continuous operation, filters in buses, taxis, and ride-share vehicles need to be robust and highly effective at maintaining consistent air quality.

Technical Advantages:

- Superior Filtration Efficiency: Advanced filter media, like the one used in Car Air Cabin Filter OEM 1987432397 1K1819653, can achieve efficiencies of over 99% for particulate matter as small as 0.3 microns, including pollen, dust, soot, and even some bacteria and viruses.

- Odor and Gas Absorption: Integrated activated carbon layers effectively adsorb harmful gases such as nitrogen oxides, sulfur dioxide, formaldehyde, benzene, and unpleasant odors from traffic or industrial emissions. This is a key differentiator from basic particle filters.

- Optimized Airflow and HVAC Longevity: Low pressure drop design ensures efficient airflow through the HVAC system, maintaining cabin comfort and reducing the strain on the blower motor, thereby extending its lifespan and potentially contributing to minor fuel efficiency gains by reducing energy consumption.

- Durability and Longevity: Robust frame construction and high-quality media ensure the filter maintains its structural integrity and filtration performance throughout its recommended service interval, even in challenging environmental conditions.

- Corrosion Prevention (Indirect): By preventing moisture-laden dust and debris from entering the HVAC components, filters indirectly contribute to preventing corrosion and mold growth within the system, ensuring cleaner and healthier air.

Choosing Your Partner: Manufacturer Comparison and Customization from a China Cabin Filter Supplier

Selecting the right china cabin filter supplier is a strategic decision for businesses in the automotive aftermarket, distribution, or even direct OEM supply chains. Beyond competitive pricing, key factors such as quality certifications, R&D capabilities, production flexibility, and customer support differentiate top-tier suppliers.

Key Criteria for Supplier Comparison:

- Certifications and Standards: Look for suppliers with ISO/TS 16949 (now IATF 16949) for automotive quality management, ISO 9001 for general quality management, and adherence to specific filter testing standards (e.g., ISO 11155, DIN 71460). These indicate a commitment to systematic quality control.

- R&D and Innovation: A forward-thinking supplier invests in research and development to create new filter media, improve existing designs (e.g., for reduced pressure drop or enhanced PM2.5 filtration), and adapt to emerging automotive technologies.

- Production Capacity & Lead Times: Assess their ability to meet your volume requirements, especially for large orders, and their track record for consistent on-time delivery.

- Customization Capabilities (OEM/ODM): Can they produce filters tailored to specific vehicle models, unique dimensions, or particular performance criteria? A strong china car air filter supplier should offer robust OEM/ODM services.

- Technical Support & After-Sales Service: Reliable partners provide comprehensive technical data, installation guidance, and responsive support for any product-related inquiries or issues.

Customized Solutions: Tailoring Filtration for Specific Needs

Beyond standard replacement parts, a leading china cabin filter supplier excels in providing customized filtration solutions. This involves working closely with clients to develop filters that meet unique specifications, which might include:

- Specific Dimensions and Fitment: Developing filters for niche vehicle models or specialized heavy-duty equipment where standard sizes are unavailable.

- Enhanced Performance Requirements: Designing filters with higher PM2.5 efficiency, increased activated carbon content for superior odor absorption, or anti-microbial treatments for sensitive applications.

- Private Labeling and Branding: Offering clients the ability to brand filters with their own logos and packaging, reinforcing their market presence.

- Material Optimization: Selecting specific media types to combat particular pollutants prevalent in a target market (e.g., high-sulfur regions requiring more robust gas filtration).

This bespoke approach ensures that clients receive precisely engineered solutions that align with their business objectives and market demands, whether they are sourcing a china car oil filter supplier or a specialized air filter manufacturer.

Application Cases and Client Success Stories

The tangible impact of high-quality cabin air filters is best illustrated through real-world applications and client success stories. While specific client names may be confidential, the scenarios demonstrate the value proposition of a reliable china cabin filter supplier.

- Case Study 1: Major European Aftermarket Distributor

A leading European automotive aftermarket distributor faced challenges with inconsistent quality and lengthy lead times from their previous filter supplier. Partnering with a specialized china cabin filter supplier allowed them to streamline their supply chain, receiving ISO/TS 16949 certified filters (like the Car Air Cabin Filter OEM 1987432397 1K1819653) with guaranteed performance. This partnership resulted in a 20% reduction in customer complaints related to filter performance and a 15% improvement in stock turnover due to reliable delivery schedules.

- Case Study 2: North American Fleet Management Company

A large fleet management company operating in heavily polluted urban areas required cabin filters with superior gas and odor absorption capabilities. Their prior filters were ineffective against the strong smells of city traffic. Our selected china cabin filter supplier provided custom-engineered filters with a higher density of activated carbon and specialized non-woven media. This tailored solution significantly improved driver comfort and air quality perception within their fleet, leading to positive driver feedback and extended filter service intervals in challenging conditions, reducing the frequency of car cabin air filter change.

- Case Study 3: Asian Automotive OEM for Economic Models

An automotive OEM focusing on budget-friendly vehicles needed a cost-effective yet reliable cabin filter solution that met basic filtration standards. A flexible china car cabin filter supplier offered a value-engineered filter that met their cost targets without compromising on essential particle filtration performance. The supplier's ability to scale production efficiently was crucial for supporting the OEM's high-volume manufacturing lines, demonstrating expertise not only in cabin filters but also in general automotive filtration, including elements often produced by a china oil filter supplier or china fuel filter supplier.

Ensuring Trustworthiness: FAQs, Delivery, and Warranty from a Premier China Cabin Filter Supplier

Building long-term B2B relationships hinges on trust, transparency, and reliable support. A reputable china cabin filter supplier prioritizes these aspects, offering clear policies and responsive customer service.

Frequently Asked Questions (FAQs):

- Q: What is the typical lead time for a bulk order of cabin air filters?

A: For standard OEM equivalent models like the Car Air Cabin Filter OEM 1987432397 1K1819653, lead times typically range from 30-45 days after deposit and order confirmation. Custom orders may require an additional 15-20 days for tooling and sample approval.

- Q: What quality certifications do your products hold?

A: Our manufacturing facilities are IATF 16949 and ISO 9001 certified. Products undergo rigorous testing according to international standards such as ISO 11155 and DIN 71460, ensuring performance comparable to or exceeding supertech cabin air filter standards.

- Q: Do you offer private labeling or custom packaging solutions?

A: Yes, we provide comprehensive OEM/ODM services, including private labeling, custom branding, and bespoke packaging design to meet your specific market requirements.

- Q: What is your warranty policy for cabin air filters?

A: We offer a standard 12-month or 15,000-mile (whichever comes first) warranty against manufacturing defects from the date of purchase. Our commitment is to quality and customer satisfaction.

- Q: How do you ensure consistency in product quality across large production runs?

A: We implement a multi-stage quality control process, including raw material inspection, in-process checks at each manufacturing stage (pleating, assembly), and final performance testing using advanced laboratory equipment. Statistical Process Control (SPC) is utilized to maintain consistent quality.

Delivery Cycle and Logistics:

Efficiency in delivery is paramount for maintaining supply chain fluidity. A leading china cabin filter supplier leverages established logistics networks to ensure timely and cost-effective delivery worldwide. This includes options for sea freight for bulk orders and air freight for urgent shipments, with comprehensive tracking and dedicated logistics support. Typical delivery to major ports can range from 20-35 days for sea freight, depending on the destination.

Dedicated Customer Support:

Beyond sales, continuous support is vital. A professional china car air filter supplier provides dedicated account managers, technical assistance, and responsive communication channels to address any queries, from technical specifications to order status updates. This comprehensive approach ensures a seamless and reliable partnership for businesses sourcing automotive filters.

Conclusion: Partnering for Filtration Excellence

The role of a trusted china cabin filter supplier in the global automotive industry cannot be overstated. As air quality concerns grow and vehicle technologies evolve, the demand for high-performance, reliable, and cost-effective filtration solutions will only intensify. By combining advanced manufacturing processes, rigorous quality control, and a commitment to customer-centric solutions, top-tier Chinese manufacturers are well-positioned to meet these challenges. Partnering with such a supplier ensures access to state-of-the-art products like the Car Air Cabin Filter OEM 1987432397 1K1819653, superior technical expertise, and a resilient supply chain, empowering businesses to thrive in the dynamic automotive aftermarket.

References

- International Organization for Standardization (ISO). ISO 11155-1: Road vehicles — Air filters for passenger compartments — Part 1: Test for particulate filtration.

- International Organization for Standardization (ISO). ISO/TS 19713-1: Road vehicles — Air filters for passenger compartments — Part 1: Test for gas filtration.

- Society of Automotive Engineers (SAE). J 726: Air Cleaner Test Code.

- Freudenberg Filtration Technologies. Global Market Report on Automotive Filters, 2022.

- Filter Manufacturers Council (FMC). Technical Bulletin: Understanding Cabin Air Filters.

This is the last article

-

Reliable China Cabin Filter Supplier | Quality Car Filters

NewsAug.21,2025

-

High-Performance Automobile Air Filter | Carbon & Turbo Options

NewsAug.19,2025

-

Car Air Filter 17801-31090 17801-0P010 OEM Quality | QINGHE COUNTY ANNAITE AUTO PARTS CO.,LTD

NewsAug.18,2025

-

Car Air Filter 17801-31090-OEM Quality|QINGHE COUNTY ANNAITE AUTO PARTS CO.,LTD

NewsAug.18,2025

-

Glass Food Storage Container with Lid - High Borosilicate Glass | QINGHE

NewsAug.18,2025

-

High Borosilicate Glass Food Storage Containers-QINGHE COUNTY ANNAITE AUTO PARTS CO.,LTD

NewsAug.18,2025