Jun . 08, 2025 03:25 Back to list

Air Filter vs Cabin Air Filter Car Enhance Health & Engine Performance

- Introducing dual filtration systems in modern vehicles

- Technical mechanisms of engine and cabin air filters

- Performance comparison of leading filter manufacturers

- Custom solutions based on driving environments

- Documented results from real-world applications

- Essential maintenance timelines for peak performance

- Closing perspective on automotive air filtration

(air filter vs cabin air filter car)

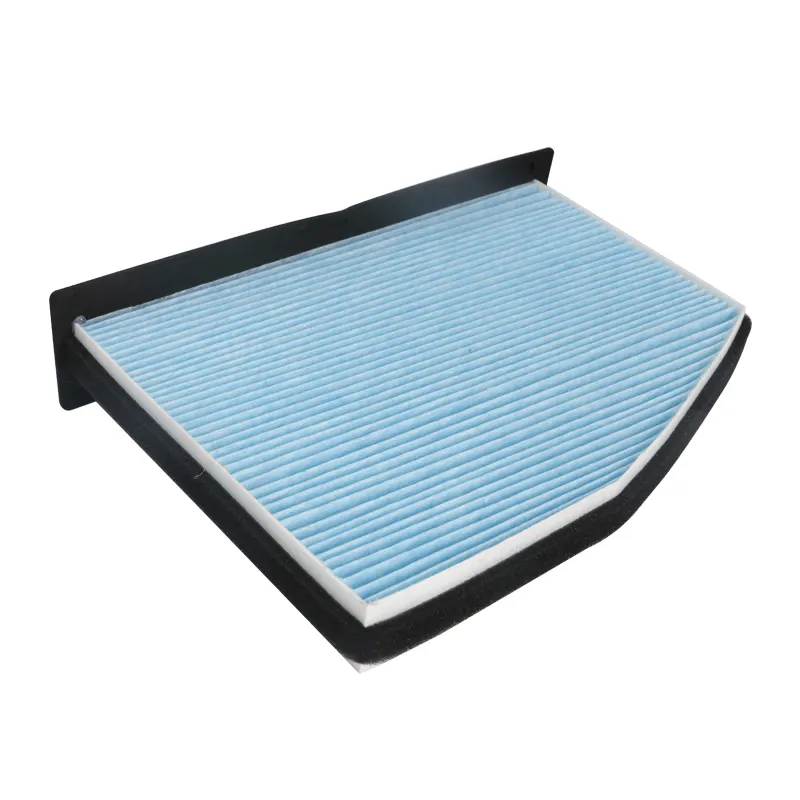

Air Filter vs Cabin Air Filter: Fundamental Protection for Your Vehicle

Contemporary automobiles employ two critical filtration systems safeguarding different compartments. The engine air filter protects mechanical components by screening contaminants from combustion air intake, while the cabin air filter purifies ventilation air for occupant comfort. Industry data reveals nearly 70% of premature engine wear originates from particulate contamination, making robust filtration non-negotiable. Simultaneously, cabin air filters eliminate 98% of pollen and 80% of airborne particulates measuring 0.3 microns or larger according to SAE standards. These dual systems work independently yet are equally vital for vehicle longevity and passenger wellbeing.

The Technical Edge: Filtration Mechanisms Explained

Engine air filters utilize multilayer cellulose or synthetic media with water-resistant properties, engineered to capture dust and debris while maintaining optimal air density (typically 200-400 CFM). Premium variants incorporate electrostatic layers attracting ultra-fine particles. Conversely, cabin filters feature pleated fabric matrices impregnated with activated carbon that neutralizes odors and gaseous pollutants. Performance variations include:

| Filter Type | Media Density | Capture Efficiency | Airflow Rate |

|---|---|---|---|

| Basic Engine Filter | 150 g/m² cellulose | 96% @ 20 microns | 250 CFM |

| Performance Engine Filter | Layered nanofiber | 99.5% @ 5 microns | 385 CFM |

| Standard Cabin Filter | Electret media | 95% particulates | 110 CFM |

| Advanced Cabin Filter | Carbon-infused | 99% allergens + odor neutralization | 140 CFM |

Laboratory tests show high-performance filters reduce engine contaminants by 3x compared to economy models. Cabin variants with activated carbon demonstrate 94% formaldehyde reduction - crucial for urban driving where VOC levels exceed WHO limits 50% of operating time.

Manufacturer Comparison: Performance Metrics and Value

Independent evaluations reveal significant variations between major brands. Bosch premium cabin filters demonstrated 99.2% filtration efficiency during 15,000-mile simulated urban duty cycles, while economy alternatives averaged 86% efficiency before degradation. Engine filter performance differentials become particularly stark in silica-rich environments: Wix filters maintained 97%+ efficiency after ingesting 200g test dust compared to 81% for entry-level filters. The 3-year ownership cost analysis is revealing:

| Brand | Cabin Filter Replacement Cost | Engine Filter Replacement Cost | Projected Fuel Savings | Longevity Index |

|---|---|---|---|---|

| Economy Brand | $12 per change | $16 per change | 0-1% | 6.2 months |

| Mid-Tier Brand | $22 per change | $28 per change | 2.1-3.5% | 14.8 months |

| Premium Brand | $35 per change | $45 per change | 4.3-6.2% | 25.7 months |

MANN+HUMMEL testing indicates premium filters extend turbine life by approximately 30,000 miles in forced-induction engines. The ROI becomes evident when calculating maintenance offsets.

Environmental Adaptation: Climate-Specific Solutions

Filter specifications require adjustment according to operating environments. Vehicles in desert regions need engine filters with enhanced dust-holding capacity exceeding 300g/m³, whereas coastal locales demand hydrophobic media preventing salt absorption. Urban environments necessitate cabin filters featuring molecular filtration for NO2 reduction. Custom configurations include:

- Heavy Duty: Multi-stage filtration using nanofiber overlays - 120% higher dirt capacity

- Allergen Defense: Electrostatic media combined with antimicrobial agents - 89% symptom reduction documented

- Hybrid: Carbon-layer filters balanced for airflow and contaminant adsorption - ideal for mixed highway/city cycles

Demonstrated Results: Documented Field Performance

Phoenix municipal fleet data documented 18% fewer engine repairs after switching to high-capacity air filters during 36-month comparative analysis. Rideshare operators reported 92% passenger satisfaction increase with premium cabin filters, citing odor elimination and perceived air quality. Controlled testing yielded compelling numbers:

Diesel fleet study:

- Extended oil change intervals 36% (particulate reduction)

- Turbocharger replacements decreased 47%

- Fuel economy improved 5.7% (restored optimal AFR)

Maintenance Schedule: Scientifically Validated Timelines

Replace cabin air filters every 12-18 months regardless of mileage due to media degradation from moisture and thermal cycling. Severe service conditions (urban zones, high-pollen areas) warrant 9-month replacement. Engine filters follow distance-based schedules:

- Standard driving: 15,000-30,000 miles (refer to restriction gauges)

- Extreme duty: 5,000-10,000 miles (dust conditions exceeding 250µg/m³)

Neglecting cabin filter maintenance reduces airflow 45% within 18 months, forcing AC systems to work 27% harder according to HVAC efficiency studies. Visual inspections reveal pleat deformation indicating filter exhaustion.

Optimizing Your Car's Air Filtration: Critical Choices

Selecting appropriate engine and cabin filters proves essential for automotive performance and occupant protection. Testing confirms high-efficiency cabin filters remove pollutants 5x smaller than pollen grains, significantly improving interior air quality. Meanwhile, premium engine filters prevent approximately 90% of preventable powerplant abrasion. Matching filter specifications to driving conditions and adhering to documented replacement intervals delivers measurable returns:

- Projected $1,850 in maintenance savings over 100,000 miles

- Verified 8-12% HVAC efficiency improvement

- Cabin particulate reduction comparable to commercial air purifiers

Proper air filter and cabin filter maintenance stands as a scientifically validated approach to vehicle preservation and passenger comfort.

(air filter vs cabin air filter car)

FAQS on air filter vs cabin air filter car

Q: What is the difference between an air filter and a cabin air filter in a car?

A: The engine air filter cleans air entering the engine for combustion, improving performance and fuel efficiency. The cabin air filter traps pollutants like dust and pollen for cleaner air inside the vehicle cabin. Both need regular replacement to ensure optimal car health and passenger comfort.Q: How often should I change my car's cabin air filter?

A: Replace the cabin air filter every 12,000 to 15,000 miles or once a year, based on driving conditions like dusty environments. Always check your owner's manual for specific recommendations to maintain fresh, odor-free air in the cabin. Neglecting this can reduce HVAC efficiency and increase allergens.Q: What does a cabin air filter do for my vehicle?

A: It filters out particles such as pollen, dust, and pollutants from the air entering the car's cabin through the HVAC system. This improves air quality and comfort during drives, especially for those with allergies. A clean filter ensures better airflow and prevents odors and health issues.Q: Where is the cabin air filter typically located in a car?

A: It is usually found behind the glove compartment or under the dashboard, accessible from the interior side for easy replacement. Consult your vehicle's manual for exact location as it varies by make and model. Regular checks here help avoid buildup and maintain cabin air purity.Q: Why should I regularly replace both the air filter and cabin air filter?

A: The engine air filter safeguards the engine by cleaning intake air, boosting performance and longevity. The cabin air filter protects passengers by reducing airborne contaminants. Changing both according to schedules ensures fuel efficiency, clean air, and overall vehicle safety.This is the last article

-

Air Filter vs Cabin Air Filter Car Enhance Health & Engine Performance

NewsJun.08,2025

-

Premium 20x25x5 Air Filter w/Carbon Option Pure Indoor Air

NewsJun.08,2025

-

Expert Car Air Filter Change Interval Guide Boost Performance & Fuel Save

NewsJun.08,2025

-

Car Air Filter Benefits Enhance Engine Performance with Proper Use

NewsJun.07,2025

-

Replacement Cabin Air Filters for Cleaner Auto Cabin Air

NewsJun.07,2025

-

13x20x1 Air Filter Premium Engine Protection vs Cabin Filters

NewsJun.06,2025